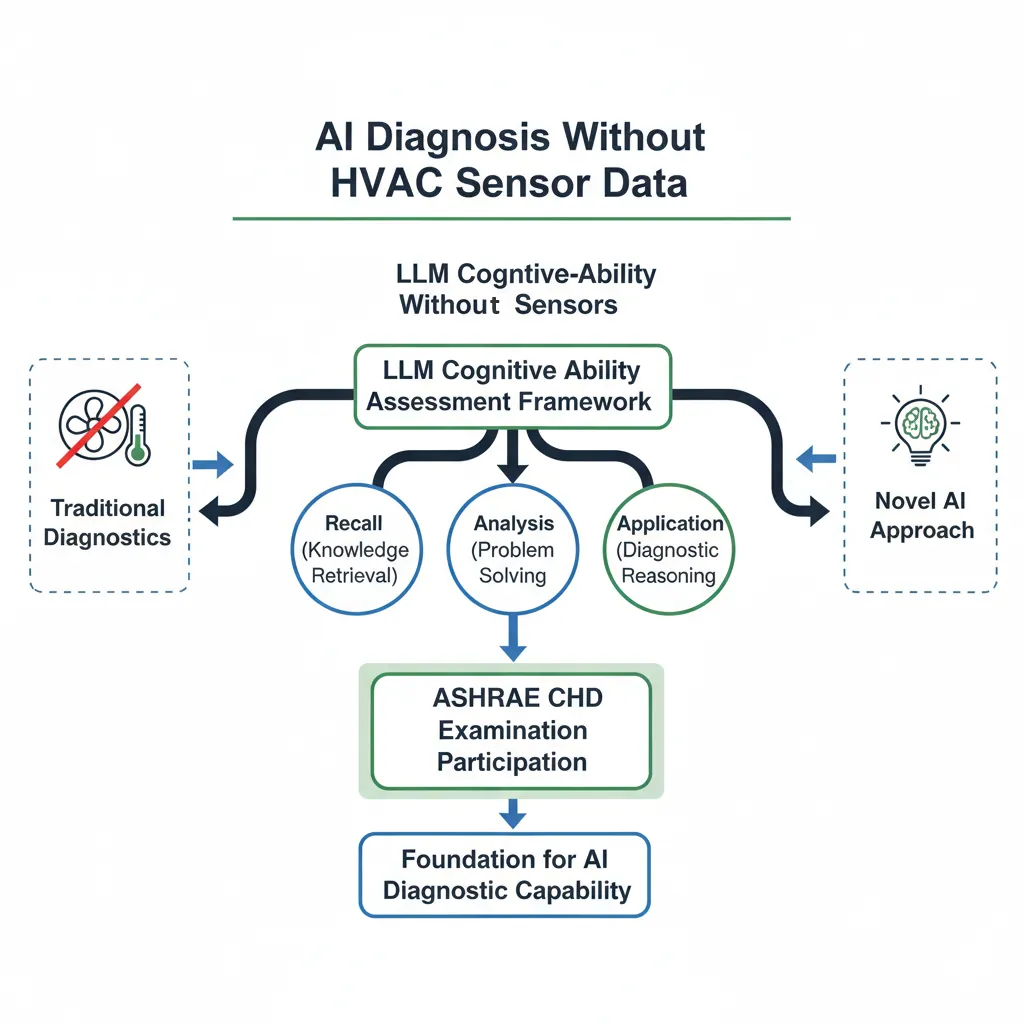

Traditional HVAC fault detection and diagnosis (FDD) methods heavily rely on the continuous reading and analysis of operational data or sensor data from HVAC systems. However, the modern, mobile-first approach utilized by ACLogics represents a breakthrough: it’s explicitly designed not to connect to sensors, relying entirely on the professional user’s input detailing the system problem.

This paradigm shift is possible because ACLogics is built upon the immense logical, cognitive, and knowledge capabilities of state-of-the-art Large Language Models (LLMs). Researchers investigating LLMs in the HVAC industry specifically explored three key cognitive capabilities crucial for professionals: recall, analysis, and application.

How Cognitive AI Replaces Sensor Data

1. Powerful Recall

Recall refers to the ability to remember or recognize specific knowledge. An excellent HVAC engineer requires a solid grasp of key concepts, principles, and technical information. When a user inputs a problem (e.g., “compressor is running but no cooling”), the LLM immediately leverages its vast repository of information to recall all relevant codes, definitions, and troubleshooting steps.

GPT-4, the top performer in this category, achieved the highest accuracy (76%) on recall capability questions. This means when you describe a symptom to ACLogics, it doesn’t need to read sensor outputs—it draws from a comprehensive knowledge base that includes:

- Equipment specifications and operating parameters

- Failure mode libraries and common troubleshooting patterns

- Code requirements and industry standards

- OEM service bulletins and technical documentation

2. Sophisticated Analysis

Analysis involves the capacity to analyze the given information and draw upon various sources to generate accurate responses. ACLogics applies this skill to the user’s narrative input, diagnosing root causes based on system requirements, design knowledge, and legal guidelines.

GPT-4’s analysis capability is exceptionally high, scoring nearly 77% accuracy in tests involving deep insights and complex sequencing tasks. This strength allows the tool to:

- Identify critical sequencing in troubleshooting steps

- Understand the importance of minimizing simultaneous heating and cooling to improve energy efficiency

- Apply systematic thinking to break down complex problems into manageable steps

- Connect symptoms to root causes using domain expertise

Why This Matters for Field Technicians

By focusing on these deep cognitive functions, ACLogics enables communication with AI models to help solve complex, repetitive, and time-consuming tasks related to the design and operation of HVAC systems, ultimately leading to higher productivity and lower labor costs.

This approach proves that AI can indeed think and learn like professionals in the HVAC industry, even without a direct data stream. For technicians in the field, this means:

- No expensive sensor installations required

- Faster diagnosis through natural language description

- Accessible to all regardless of equipment age or connectivity

- Reliable knowledge base that doesn’t depend on system integration

The Cognitive Advantage

Traditional sensor-based FDD systems require:

- Physical installation and calibration

- Continuous monitoring infrastructure

- Integration with building automation systems

- Significant upfront investment

ACLogics eliminates these barriers by leveraging the cognitive power of advanced AI. When you describe what you see, hear, and measure, the AI’s recall and analysis capabilities work together to provide professional-grade diagnostics—proving that knowledge-driven troubleshooting can be just as effective as data-driven approaches, often with greater flexibility and lower cost.

The future of HVAC diagnostics isn’t just about collecting more data—it’s about understanding what that data means. And that’s exactly what cognitive AI brings to the field.